by Amy Schmidt, Director, Plastics Building and Construction, American Chemistry Council and North American Modern Building Alliance, LEED Green Associate

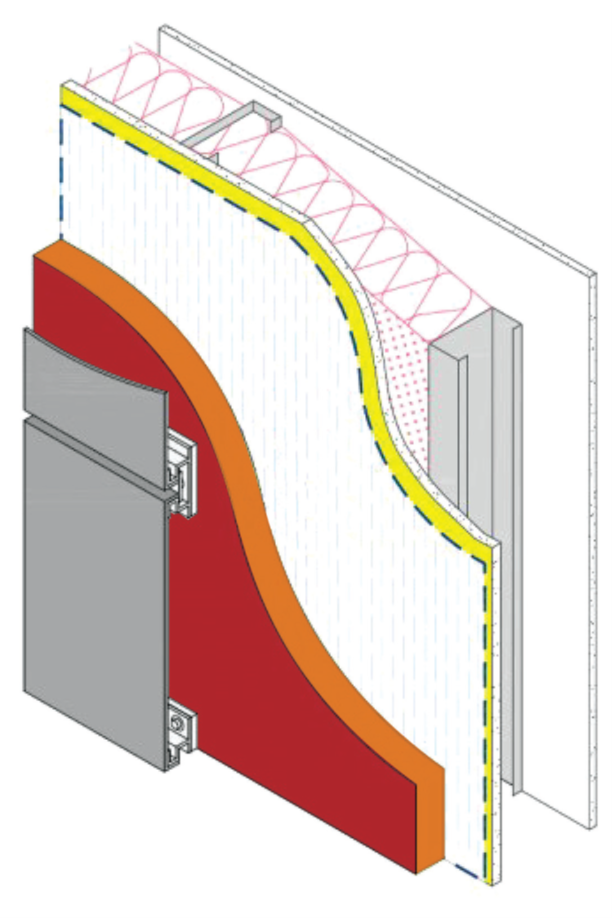

Exterior wall assemblies have become increasingly complex and critical elements of the building envelope. Advancements in our understanding of building science, coupled with the need to improve the energy efficiency and resilience of buildings, have led to innovative solutions in both building products and construction methods. Many of these innovative products are combustible, and although their use in noncombustible building elements is widely permitted under the International Building Code, both the products as well as their uses in noncombustible construction must meet fire testing and fire performance requirements.

There are three options for determining code compliance of exterior wall assemblies with the acceptance criteria of NFPA 285 when required by the building code:

1) test the specific wall assembly to be constructed;

2) third-party certified design listings; or

3) engineering analysis and judgment of a wall assembly based on NFPA 285, Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components, test data for a similar wall assembly.

The 2024 International Building Code adopted a new section in chapter 14 that codifies these three compliance methods for code enforcement of exterior wall assemblies that must be tested in accordance with NFPA 285. The new section provides for compliance with the acceptance criteria of NFPA 285 shall be established by any of the following three methods described below:

1. NFPA 285 test data, from an accredited laboratory, for the exterior wall assembly confirms specific performance of a specific assembly.

Construct what is tested: NFPA 285 test method evaluates vertical and lateral flame propagation characteristics of full-scale exterior wall assembly designs. The fire exposure simulates a fire scenario where a post-flashover fire has breached the exterior window of the room of origin, exposing the full exterior wall assembly (the interior wall cavity and both exterior and interior sides) to a flame assault and heat plume. NFPA 285 stipulates conditions of acceptance, such as vertical and horizontal flame spread not exceeding 10 feet above the window opening and 5 feet from the vertical centerline of the window opening, respectively.

2. Designs listed by an accredited and approved agency will be based on successful NFPA 285 testing of the exterior wall assembly and accompanying data analysis.

Construct what was listed: Many manufacturers develop and maintain third-party certifications for assemblies tested in accordance with NFPA 285. These certifications are provided by duly accredited agencies and take the form of design listings and code evaluation/research reports that recognize specific assembly configurations and components. Design listings for assemblies complying with NFPA 285 are available directly from certification agencies through online product directories. Code evaluation/research reports are also available directly from certification agencies through online directories such as those provided by the International Code CouncilEvaluation Service Intertek, Underwriter’s Laboratories, and others.

3. Analysis and judgment of a wall assembly based on NFPA 285 test data for a similar wall assembly

Construct with approved analysis judged fire safe: The data collected during an NFPA 285 test records the real-time dynamic behavior of each individual assembly layer. When combined, the data from all assembly layers describes how heat and fire moved throughout the assembly in all three dimensions. It is the quality of this test data that makes it possible for qualified individuals, using experience and sound principles of fire science and fire engineering, to evaluate the performance effects of certain modifications to tested assemblies and to confirm that the alternative assembly will continue to comply with the acceptance criteria of NFPA 285. These engineering analyses extending full-scale NFPA 285 test results determine equivalence whether a modified assembly will perform at least equivalently to the tested assembly in terms of the acceptance criteria.