This is the third in a multi-part series of articles on the topic of testing and design for exterior wall assemblies that the building codes require to comply with NFPA 2851. These articles are intended to promote effective communication between stakeholders regarding this important fire safety topic for the design and construction of code-compliant exterior wall assemblies.

Begin As Soon As Possible

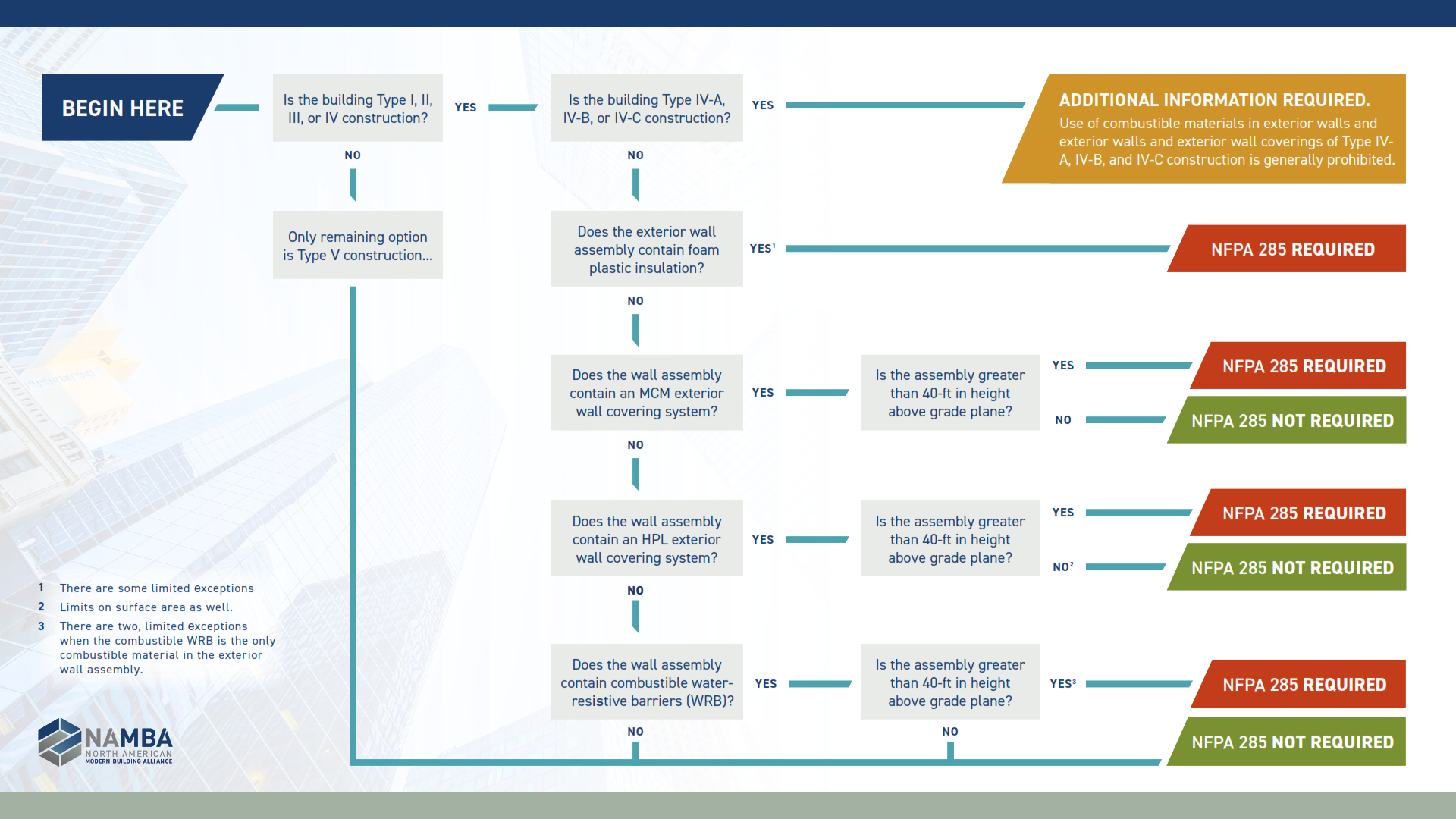

It is beneficial to begin investigating NFPA 285 compliance requirements and exterior wall design information as soon as possible in a project. Is testing and compliance with NFPA 285 likely to be required? If so, then what code provision(s) or material(s) is prompting the requirement? Are there any limits or exceptions to the required testing?

When testing and compliance with NFPA 285 is required, requesting product manufacturers or suppliers to provide, “…a copy of the NFPA 285 test report…,” is not as simple of a request to fulfill as it might seem. A test report for an assembly that exactly matches the proposed design may not be available. Testing efforts usually include an assessment or consideration of what would present a “worst case” or benchmark test that may then be used as the basis for extending successful results to other assemblies that will perform at least as well as the benchmark. Depending on the specific design, extension of successful test results for a similar design may require significant time and additional information or data that is not readily available. Also, test reports may contain proprietary business information that may not be appropriate for distribution. Open and frank discussion between designers and manufacturers (and consultants) is essential to support good-faith communication of necessary and appropriate design information between the stakeholders.

With NFPA 285 tested “worst case” designs not likely to match up with actual to-be-constructed designs, how does a designer collect and interpret the necessary information to assure the project design will meet the acceptance criteria of NFPA 285? The answer is to do the necessary research, ask the right questions, be specific, and work collaboratively with building product manufacturers and consultants.

It is also important to understand that even if there is a successful NFPA 285 test exactly matching each exterior wall assembly for a given project, analysis and extension of successful NFPA 285 test data may become necessary to address situations where limited, but unique project conditions arise (e.g., transitioning between different exterior wall coverings, limited areas of constrained dimensions or complex geometries, etc.) that cannot be assembled in conformance with the assemblies provided for the majority of a project’s exterior wall area.

Locate the Necessary Information

Today’s exterior wall assemblies have become complex systems. They are tasked with providing all the control functions (water, air, thermal, and vapor) of the building envelope, resisting certain structural or design loads, and meeting strict fire performance requirements for fire safety of the building. Satisfying all of these requirements has led to wall designs with multiple discrete and overlapping layers, often with multiple combustible components.

When it comes to NFPA 285, design and compliance information is spread among more sources and locations. In most cases, building product manufacturers will serve as the initial, if not primary, source of information.

The first resource to begin research is manufacturers’ respective websites for published NFPA 285 compliance information. Technical Data Sheets, Design and Installation Guides, and engineering judgement / analysis letters, among others, are typical documents where NFPA 285 design information is published. A second resource for researching NFPA 285 design and compliance information is online directories published by approved agencies. Third-party certification (i.e., listing or labeling) of wall assemblies for compliance with NFPA 285 is not required by the International Building Code® (IBC®)2, however, some manufacturers choose to have wall designs certified for compliance with NFPA 285. A third resource is building code compliance research reports, also published by approved agencies in online directories, whose scope of recognition includes both the International Building Code® (IBC®) and NFPA 285.

Bearing in mind that modern wall designs may contain multiple combustible components from different manufacturers, it may prove necessary to contact and collect information from multiple manufacturers, perhaps including fire testing or code consultants, to bring all the pieces together. Designers may find that manufacturers of foam plastic insulation tend to have more NFPA 285 information than other product manufacturers because the IBC requires NFPA 285 where foam plastic is used in or on exterior walls, of any height, in Type I, II, III, and IV construction.

Designers and manufacturers are encouraged to remember that NFPA 285 tests and extensions of successful NFPA 285 tests are evaluations of wall assemblies as a complete system; in other words, they focus on the assembly. It is equally important for all parties to remember that (a) any wall design must tie back to at least one tested assembly, and (b) sometimes testing a proposed wall design to NFPA 285 is the proper course of action.

Discussing the Details

Reasonable questions for discussion between stakeholders about NFPA 285 design and test information, the extension of results for assemblies meeting the requirements of NFPA 285, and their use in determining compliance of wall designs for specific projects include the following, but be sure to modify as needed for your own circumstance:

Discussion points regarding NFPA 285 test information:

- To what edition of NFPA 285 was the test conducted and what edition of NFPA 285 is referenced in the applicable building code?

- How do the components, their installation (e.g., thickness, installation rate, fastening schedule, joint locations, etc.), and the complete configuration of one or more assemblies successfully tested to NFPA 285 compare to the proposed design?

- How was the perimeter of the window opening (head, jambs, and sill) treated in the tested assembly?

- How does the as-tested window perimeter treatment compare to the proposed design?

- For example, the 2019 Edition of NFPA 285 introduced a generic window header design. Was the generic window header design used in the test or a design specified by the manufacturer?

- Are detailed drawings or clear and detailed descriptions of the tested wall assemblies (including installation details) available?

- Are drawings available for the proposed design?

- Are there any third-party design listings for assemblies complying with NFPA 285?

- Are there any third-party code compliance research reports recognizing use in exterior walls of Types I, II, III, or IV construction under the IBC based on compliance with NFPA 285?

- Are there evaluations extending assemblies that meet NFPA 285?

Discussion points regarding extensions of successful NFPA 285 tested assemblies may include:

- To what edition of NFPA 285 was each test conducted?

- To what edition of the IBC, and referenced edition of NFPA 285, is compliance required?

- Generic extensions:

- What is the rationale for extending configuration details of the tested design to the alternatives? For example extending results of a test conducted using a light-gage metal-framed (LGMF) backup wall to a concrete masonry unit (CMU) backup wall is permissible because…, or extending results to a water-resistive barrier other than the one in the tested assembly is permissible because…, etc.

- Does the evaluation include detailed drawings or clear descriptions of the wall assemblies?

- Assembly-specific extensions:

- See “Discussion points regarding NFPA 285 test data” above.

- How do the proposed designs, or aspects of the proposed designs, compare with the tested assemblies referenced in the evaluation?

- Are detailed drawings and installation details included?

- What is the rationale for extending the configuration details of the tested assemblies to the alternative designs?

- What, if any, additional supporting data was considered in the evaluation?

- How does the evaluation support a finding that the alternatives will continue to comply with NFPA 285?

1 NFPA 285 Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components, available from the National Fire Protection Association (NFPA), Quincy MA.Congress International (SBCCI).

2 International Building Code® (IBC®), available from the International Code Council (ICC), Washington, DC.